Objectives

The BioCel3D project aims to develop a 3D printing technology to manufacture a biodegradable continuous cellulose fibre reinforced composite for structural applications using agricultural waste and cellulose obtained by bacterial cultivation as raw material for the reinforcing fibres. The project has the following specific objectives:

- Develop a green technology for extracting nanocellulose from the waste of agricultural waste, as feedstock for electro-spinning, as well as a methodology for obtaining the continuous reinforcement directly from bacteria cultivation.

- Develop a process that keeps the electro spun fibres aligned.

- Develop a chemical treatment to reduce the inherent moisture sensitivity of cellulose fibres and to improve the fibre/matrix compatibility at the same time, based on polydopamine.

- Develop a continuous and hierarchical reinforcement with dissipative mechanisms at the fibre/matrix interface by fine tuning interfaces at the nanoscale and using a biodegradable thermoplastic as matrix, in order to increase toughness whilst keeping the strength of the fibres.

- 3D printing validation of the material developed via printability study, sample production and testing along with simple part design and production of a demonstrator.

Work Package

| WP | Title |

| 1 | Cellulose source and nanocellulose extraction |

| 2 | Electrospinning and 3D printing filament production |

| 3 | 3D printability study and validation |

| 4 | Advanced multiscale Mechanical and physical characterization |

| 5 | Modelling of the nanocellulose alignment process and prediction of the nanofibres microstructure/mechanical property relationships |

| 6 | Coordination and management of the project |

Work Package(s)

WP1: Cellulose source and nanocellulose extraction

Leader: University of Maribor (UM)

Partners: TUG, LIST

The objective in Work Package 1 is to develop a green process for extracting nanocellulose from agricultural and textile waste, as well as to establish an efficient method for cultivating bacterial cellulose with a focus on nanofiber alignment.

Cellulose fibers possess unique structural and chemical properties that make them ideal building blocks for composite materials. With their inherent fibrillar nature, characterized by well-ordered crystalline segments and accessible amorphous regions, cellulose fibers offer a versatile precursor that can be disassembled into these structural entities. These entities exhibit exceptional mechanical and interfacial features, enabling their functionalization and utilization in various applications.

Through our research and development efforts in Work Package 1, we aim to unlock the full potential of cellulose fibers, leveraging their remarkable properties to advance the field of materials science and contribute to sustainable and innovative solutions.

Stay tuned for updates on our progress in Work Package 1 as we strive to achieve our goals and make significant contributions to the field of nanocellulose extraction and bacterial cellulose cultivation.

Note: For detailed information on our research methodologies and findings, please refer to the publications and reports generated throughout the project duration.

WP2: Electrospinning and 3D printing filament production

Leader: Luxembourg Institute of Science & Technolgy (LIST)

Partners: UM, KUL

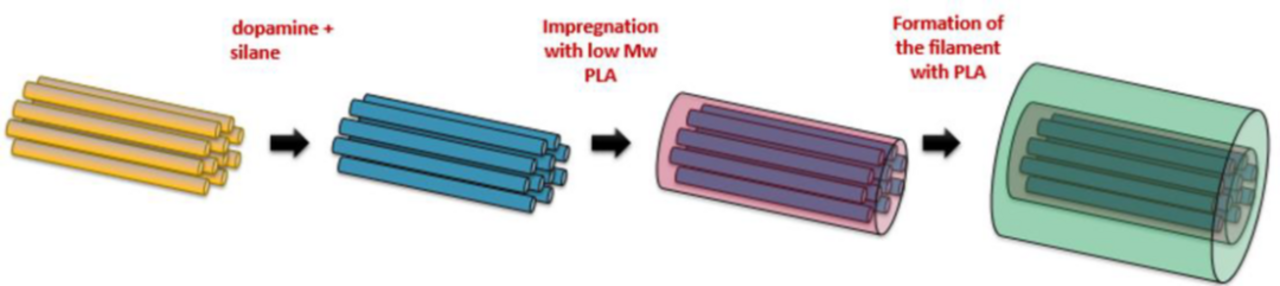

In Work Package 2, our primary objectives are to develop a method for electrospinning cellulose derivatives with a high content of nanocellulose and optimize the treatment of each individual electrospun fiber using polydopamine.

Electrospinning is a versatile technique for fabricating nanofibers with exceptional properties. By incorporating nanocellulose into cellulose derivatives, we aim to enhance the mechanical strength, flexibility, and functionality of the resulting fibers. Our research focuses on developing a robust and scalable electrospinning process to achieve high nanocellulose content in the fibers.

Through our research efforts in Work Package 2, we are pushing the boundaries of electrospinning technology and nanocellulose-based materials. Stay connected to our project updates as we make significant strides in advancing the field of electrospun fiber fabrication and treatment.

Please note that comprehensive details on our methodologies and outcomes can be found in the project publications and reports, available upon request.

WP3: 3D printability study and validation

Leader: KU Leuven (KUL)

Partners: LIST

Work Package 3 focuses on investigating the printability of the developed filament and identifying suitable process strategies for 3D printing. We aim to optimize the printing parameters and evaluate the performance of the printed parts.

Our research revolves around understanding the behavior of the material during the 3D printing process. We explore different printing techniques, including in-situ co-extrusion of the pre-impregnated yarn and extrusion of the ready-to-print filament.

Through rigorous experimentation and testing, we assess the printability of the material under various conditions, such as temperature, nozzle size, and printing speed. We aim to optimize the printing parameters to achieve high-quality prints.

Furthermore, we evaluate the performance of the printed parts, considering factors like dimensional accuracy, surface finish, and mechanical properties. Our focus is to ensure that the printed objects exhibit the desired functionality and meet the requirements of their intended applications.

Stay connected to our project updates as we delve into the world of 3D printing and assess the printability and performance of our innovative filament.

WP4: Advanced multiscale Mechanical and physical characterization

Leader: LIST

Partners: KUL, TUG

In Work Package 4, we focus on evaluating and improving the fibre-matrix bonding, material durability, and mechanical performance of the reinforcing fibres, yarns, and filaments, as well as the 3D printed materials.

Our work involves comprehensive tests and analyses to assess the mechanical properties and physical characteristics of the materials at various hierarchical microstructural levels. By understanding the relationship between these levels, we aim to enhance the overall performance and longevity of the materials.

Through experimental testing and data analysis, we gain insights into the mechanical behavior and structural integrity of the materials. This enables us to optimize the material design and enhance the fibre-matrix interaction, leading to superior performance in 3D printed objects.

Stay tuned for updates as we delve into the mechanical and physical characterization of our innovative reinforcing fibres and 3D printed materials.

WP5: Modelling of the nanocellulose alignment process and prediction of the nanofibres microstructure/mechanical property relationships

Leader: KU Leuven (KUL)

Partners: LIST, TUG, UM

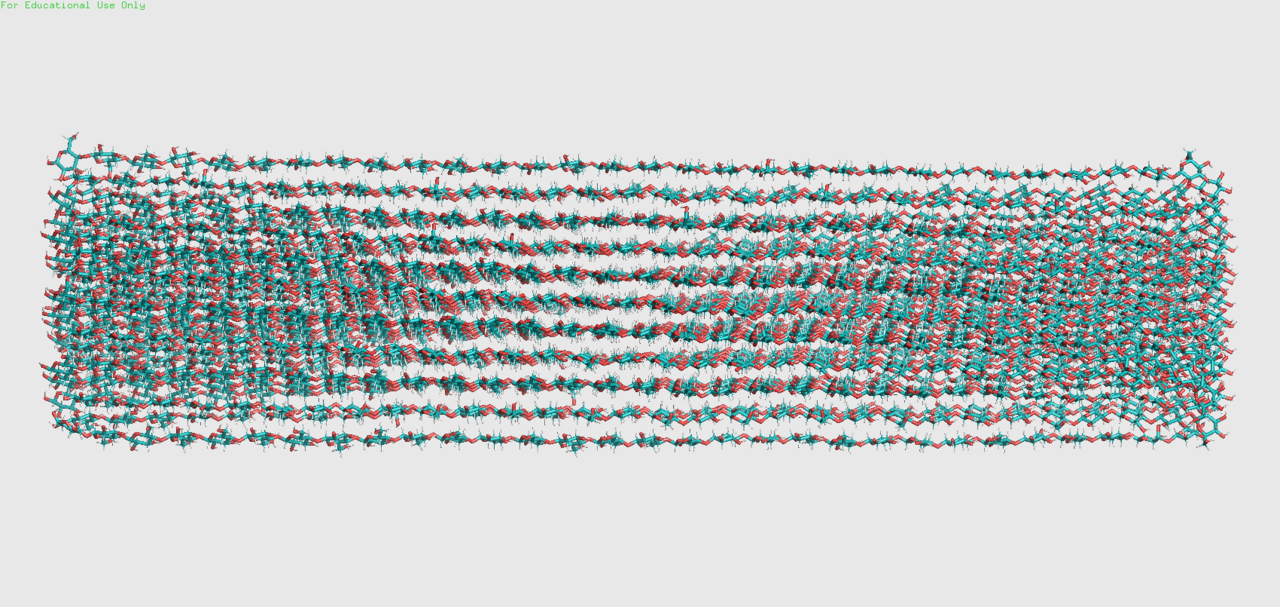

In Work Package 5, we employ advanced modelling techniques to understand the assembly and mechanical behavior of cellulose nanofibres (CNCs/NFCs). Our focus is on investigating the physico-chemical mechanisms involved in CNC/NFC aggregation, alignment, and regeneration processes.

Through molecular dynamics simulations, we analyze the electrospinning process, reorganization of CNCs/NFCs during regeneration, and the effects of polydopamine coating on mechanical and interfacial properties. These simulations complement experimental studies and provide valuable insights into nanofibre behavior.

Our modelling study helps us uncover the underlying mechanisms that drive CNC/NFC assembly and predict their intrinsic mechanical properties. By bridging the gap between theory and experiment, we gain a deeper understanding of these remarkable nanofibres.

Stay tuned for updates as we uncover the secrets of cellulose nanofibre assembly and their mechanical performance through our modelling efforts.

WP6: Co-ordination & Project Management

Leader: LIST

Partners: KUL, UM, TUG

In Work Package 6, our primary focus is to establish a strong organizational framework and support mechanisms that facilitate a seamless workflow for the project. We aim to provide clear guidance, effective communication structures, and optimal orientation to all project partners.

By maximizing the effectiveness of project activities, we ensure the timely and high-quality achievement of project results. Our dedicated team coordinates both scientific and administrative aspects, promoting efficient resource utilization and avoiding duplication of efforts.

Through effective project management and coordination, we aim to streamline processes, reduce waste of time, and enhance overall project efficiency. Our goal is to create an environment that fosters collaboration, innovation, and successful project outcomes.

Stay connected with us as we work diligently to deliver impactful results while maintaining an efficient and well-coordinated project framework.