BioCel-3D

Cellulose from waste and bacteria in electro-spinning for continuous fibre reinforced 3D printed composites

Inspiration

From the automotive and aerospace to the biomedical industries, composites show a wide range of applications. But even if the carbon and glass fibres that make up most composites have excellent properties, these fibres have a high environmental impact, particularly due to their energy-intensive production.

Natural fibres, such as cellulose, could prove to be a sustainable alternative. However, their naturalness shows several limitations: high degradability and variability as well as a complex hierarchical structuring. In this context, there is a need for developing cellulose based fibres for composite applications replacing the use of conventional natural and synthetic fibres.

Innovation

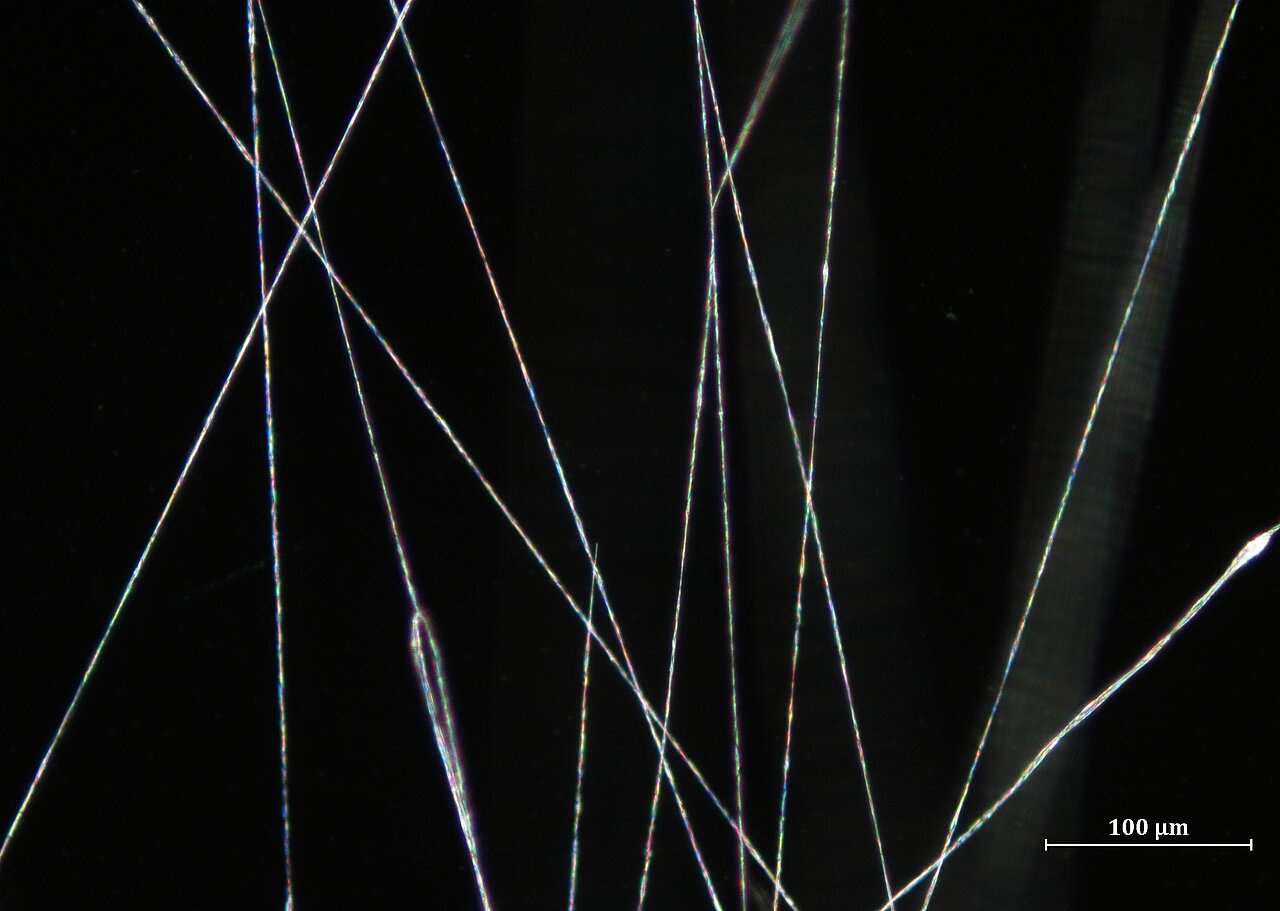

BioCel3D has the ambition to develop a brand-new generation of reinforced cellulose fibres with high mechanical properties for the design of complex 3D printed composite materials. To do so, the partners of this innovative M-ERA.NET project coordinated by LIST will make use of recycled cellulose. From textiles industries to agricultural waste as well as bacterial cellulose, the University of Maribor and Graz University of Technology will focus on the production of nanocellulose from these recycled raw materials.

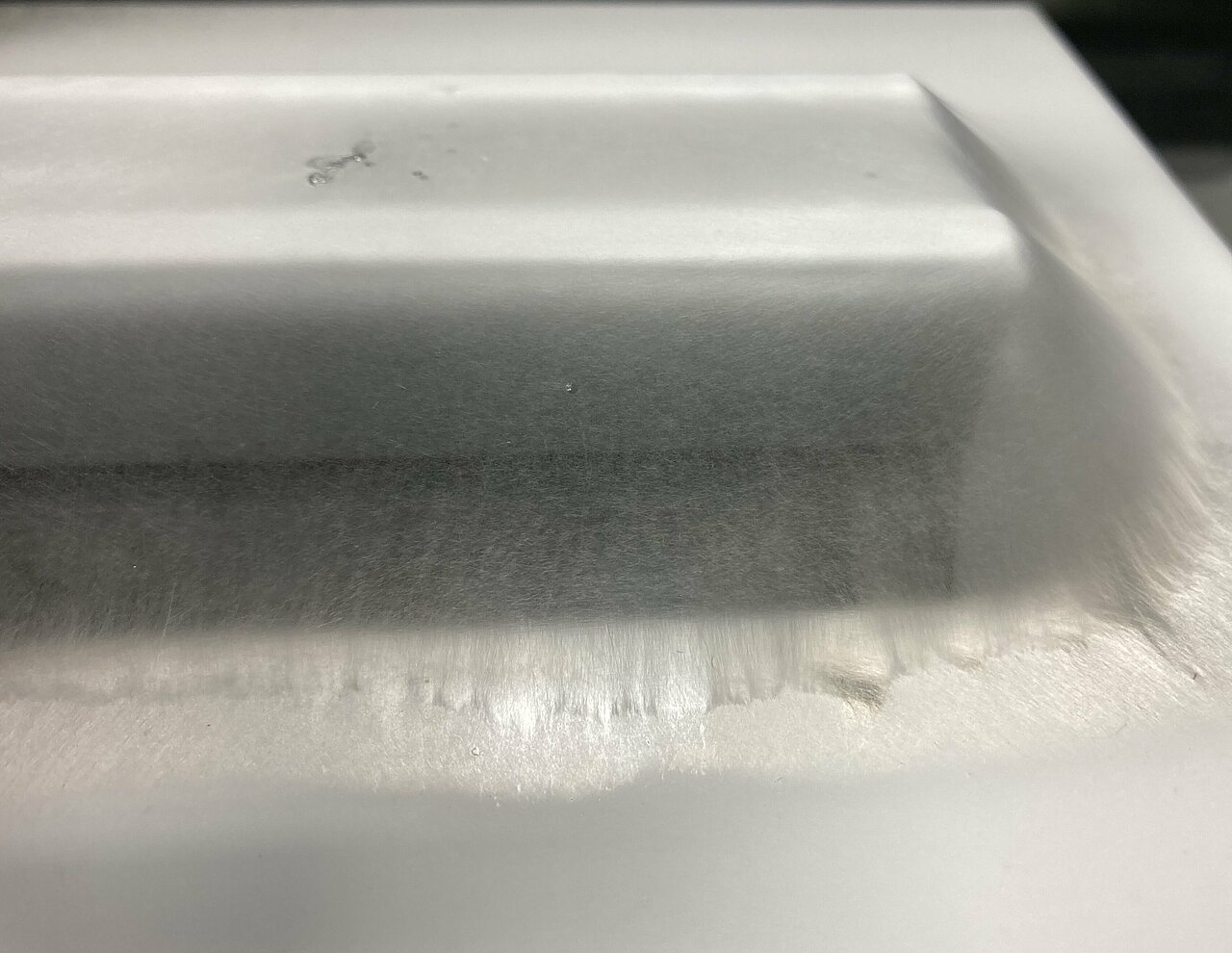

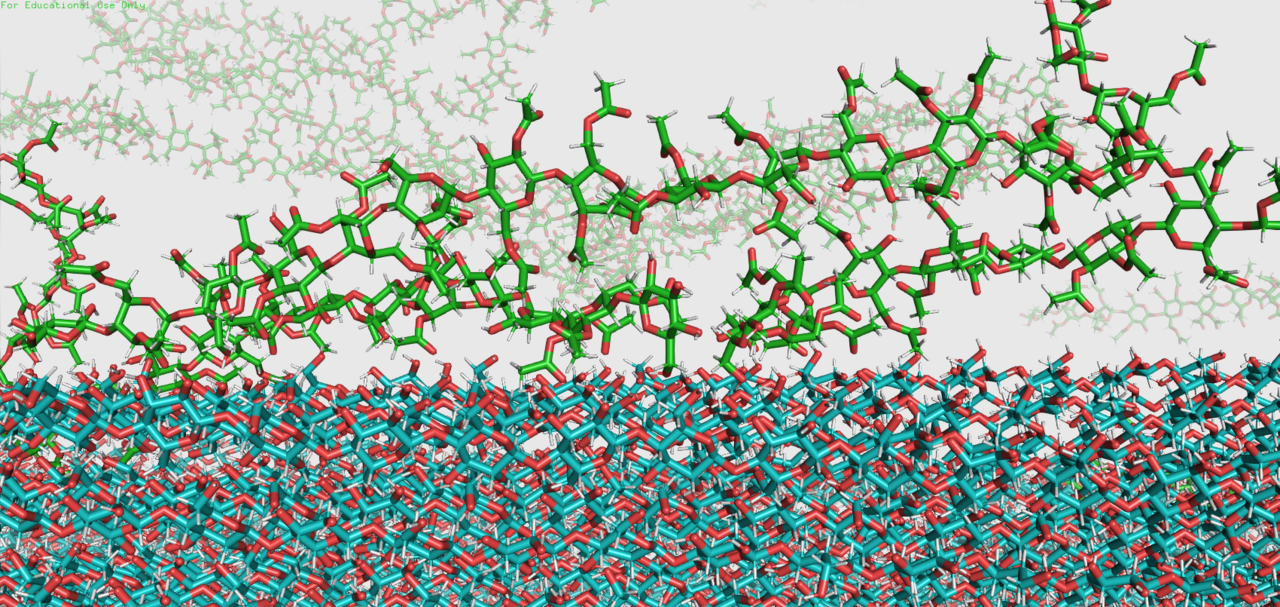

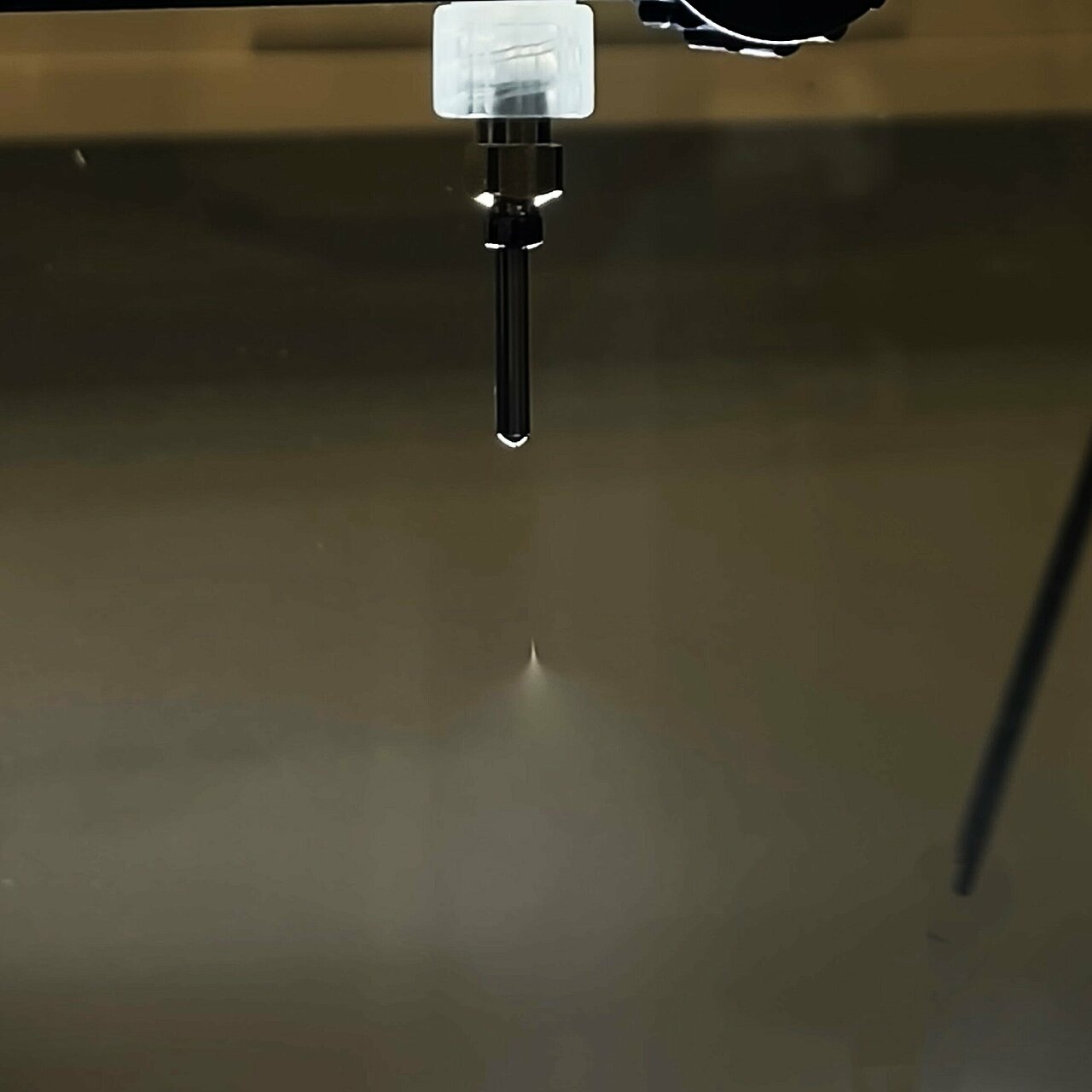

While KU Leuven will provide molecular dynamic simulations, LIST will build up the cellulose fibres by electro-spinning of the nanocellulose together with cellulose derivatives. Other biomaterials, such as dopamine, will be used with the elemental fibres within the interface in order to obtain technical fibres exempt of the usual natural fibres limitations. LIST will carry out the mechanical tests on the cellulose fibres before producing the filaments that will be used by KU Leuven for the 3D printing of composite materials.

Impact

BioCel3D expects to develop the first-of-their-kind continuous fibres reinforced 3D printed composites by electro-spinning. This innovative process would not only enable to tackle the main challenges of the use of the natural fibres into 3D printed composites but also allow significant advances in the current state-of-the-art on the domain. With the support of its industrial advisory board, the BioCel3D consortium should open the path to a new generation of natural fibres for a wide range of 3D printing applications.